Within that big car repair universe, Brake Fluid 101 grease usually comes after more prominent pieces like tires or brakes. Yet this unpretentious liquid is vital for your safety on roads.

Let’s examine for ourselves everything about brake oil, including its major characteristics and how to take care of it. A vehicle safety informed decision maker will complete this detailed brake fluid guide

What Exactly is Brake Fluid 101?

Your car’s braking system relies on the brake fluid for its effectiveness. This hydraulic fluid transmits force to generate pressure, which assists in stopping the vehicle when the brake pedal is depressed. However, not all liquid brake fluids can do this, only particular ones that have been made to withstand the harsh environment within your brake lines.

Key properties of brake fluid include:

- High boiling point: Brake fluid must resist vaporization under high temperatures.

- Low viscosity: It needs to flow quickly through the brake lines.

- Corrosion resistance: The metal components of the brake system must be safeguarded from the effects of brake fluid.

- Compatibility: Brake fluid must not harm the rubber seals and hoses.

“Brake fluid is similar to oil in your engine it’s an essential component for the good performance of your brakes. Do not take this lightly, otherwise it will be disastrous for you.” John Smith, a mechanic who has been in the business for three decades.

Various types of brake fluid are basically made up of different kinds of glycols and their ethers. Its combination imparts unique characteristics needed for satisfactory operation within the braking system in a vehicle. Unlike any other automobile fluid, however, brake fluid has to keep on performing well under different conditions including temperatures and pressures that can be considered extreme.

The Science Behind Brake Fluid Performance

To comprehend the functioning of brake fluids, a brief course in hydraulics is vital. When one steps on the pedal for braking, it causes pressure to develop in the line of brakes. This pressure is passed through brake oil to calipers that pinch the pads against rotors so as to slow down your car.

Here’s where things get interesting:

- Temperature effects: During the usage, when brakes get heated, the temperature of brake fluid may go over 500°F (260°C). This heat comes from brake pads rubbing against rotors creating friction which is then passed onto the brake fluid.

- Moisture absorption: Over time, brake fluid becomes hygroscopic by saturating itself with moisture from the surrounding atmosphere. This particular quality is a boon and bane at once. It prevents puddling of water in the brake system that may lead to rusting or even evaporating during hard brakes. Nevertheless, when more water is taken in by the liquid its temperature reduces.

- Compressibility: Brake fluid has a bit of ability to be compressed unlike the liquids such as water; therefore, it alters braking sensation and its efficiency. This property of being compressible is specifically designed so that a proper balance between responsiveness and padding can be attained in the braking system.

- Viscosity changes: The nature of brake fluid varies when subjected to different temperatures. It has to keep enough viscosity for it to be rapidly flowing at lower temperatures, while at the same time sustaining its characteristics at elevated temperatures.

In order to better understand the significance of selecting the best brake fluid and its maintenance, let’s examine each of them in detail.

The Impact of Heat on Brake Fluid

Your brakes may have a high temperature when they are used repeatedly or heavily. This heat is translated to brake fluid that might even boil if the temperature reaches boiling point. Gas bubbles are produced in the brake lines when brake fluid bubbles. The difference with liquids is that gas bubbles can be compressed which causes the brakes to feel spongy or stop working at all.

That’s why the boiling point of brake fluid is a very important feature. Various kinds of brake fluids are given different ratings according to their boiling point which will be discussed in detail while looking into DOT ratings.

The Moisture Problem

Previously stated, brake fluid takes in dampness over the years. Even when brake systems are sealed off, rubber brake hoses have minute openings that allow for moisture absorption into the fluid.

Here’s why this matters:

- Brake fluid has a significantly higher boiling point than water. The more water present in the liquid the lower boiling point the mixture will have.

- Corrosion might be caused by water in the brake mechanism system leading to the deterioration of metallic parts.

- Should temperatures be exceedingly low, there is a possibility for The water to freeze, which may possibly block the brake lines.

The freezing point of water may lead to the blockage of brake lines in the event that temperatures become extremely low.

Viscosity and Compressibility

The much engrossed viscosity of brake fluid is biased so as to offer correct flow properties. It has to be thin for easy and fast passage through narrow brake system channels as well as thick for proper feel on the pedal and deterrent to leakage.

In addition, compressibility is also an important aspect. Although brake fluid is considered as being incompressible, it actually has some compressibility. This is good thing since it helps in absorbing pressure spikes within the system and thus maintaining a uniformity in pedal feeling.

Decoding DOT Ratings: More Than Just Numbers

The brake fluid’s highly engrossed viscosity is biased to offer appropriate flow properties. It needs to be thin so that it can easily and rapidly pass through the narrow channels of the brake system while being thick enough for correct feel on the pedal and prevention of leakages.

Another important aspect is also compressibility. Though brake fluid is viewed as incompressible, it actually possesses some degree of compressibility. This is beneficial in absorbing pressure spikes in the system thereby maintaining pedal uniformity in feeling.

Let’s break down the most common brake fluid DOT ratings:

| DOT Rating | Dry Boiling Point | Wet Boiling Point | Typical Base | Common Applications |

| DOT 3 | 401°F (205°C) | 284°F (140°C) | Glycol Ether | Most passenger cars |

| DOT 4 | 446°F (230°C) | 311°F (155°C) | Glycol Ether | Performance cars, motorcycles |

| DOT 5 | 500°F (260°C) | 356°F (180°C) | Silicone | Classic cars, military vehicles |

| DOT 5.1 | 500°F (260°C) | 356°F (180°C) | Glycol Ether | High-performance vehicles |

The “wet” boiling point is particularly important because it represents the fluid’s performance after absorbing 3.7% water by volume a common occurrence in real-world conditions.

Pro tip: Always use the DOT rating recommended by your vehicle manufacturer. Using a lower rating can compromise your braking performance, especially under demanding conditions.

Understanding DOT 3 Brake Fluid

The most typical kind of brake fluid for cars owned by people is known as DOT 3. It is a liquid made from glycol, which provides excellent performance in normal driving conditions. Here are some key points about DOT 3:

- It’s the least expensive type of brake fluid.

- It has the lowest boiling point of the common DOT ratings.

- It absorbs moisture more quickly than other types.

- Most brake systems are compatible with it.

High-performance applications and extreme environments may not suit DOT 3 despite being good for the majority of driving conditions.

DOT 4 Brake Fluid: A Step Up in Performance

The boiling point of DOT 4 brake fluid is higher compared with that of DOT 3 because it has borate esters although they both contain glycol as their component. Therefore, this kind of brake fluid can withstand tougher working conditions. This makes it suitable for more demanding applications. Key features of DOT 4 include:

- Higher boiling point for better performance under heavy braking.

- Often used in vehicles with ABS or stability control systems.

- Can absorb moisture more slowly than DOT 3.

- Generally compatible with systems designed for DOT 3.

DOT 4 is often recommended for performance vehicles or those used in mountainous areas where brakes are used more heavily.

DOT 5: The Silicone Alternative

This is due to its silicone base instead of being glycol-based thus making it extremely different from DOT 3 and DOT 4.

This gives it some unique properties:

- Such fluids are not moisture absorbing as they are made with glycol.

- Among usual brake fluids, it has got the topmost boiling point.

- It’s not corrosive, making it ideal for classic cars.

- Because ABS systems and other brake fluids don’t work with it.

Determined by DOT 5, this has certain benefits; however its infrequent use in current-day automobiles is due to lack of synergy with other fluids and some braking system components.

DOT 5.1: High Performance in a Glycol Base

Individuals occasionally conflate DOT 5.1 with DOT 5, however, in contrast with them; it is a glycol based fluid similar to DOT 3 or DOT 4. Therefore this provides the high boiling point of DOT 5 in addition to compatibility with glycol-based fluids. Key points about DOT 5.1:

- Of glycols, it possesses the maximum boiling point.

- In most cases, it’s deployed in racing and high-performance interactions.

- It works with DOT 3 and DOT 4 liquids.

- Glycol-based fluids are more expensive than it.

Vehicles that have track usage or extreme driving conditions should use DOT 5.1.

Can You Mix Different Brake Fluids?

This is something people frequently ask about; are you able to mix brake fluids if they’re from different DOT ratings? The answer can be briefly put as don’t do it. Here’s why:

Chemical incompatibility: Different formulations can react unpredictably.

Performance degradation: Mixing fluids can lower the overall boiling point.

Potential system damage: Some combinations can cause corrosion or seal damage.

If you’re in a pinch and absolutely must top off with a different fluid, stick to the following rules:

- DOT 5 (silicone base) should not be mixed at any time with another type.

- DOT 3 can be mixed with either DOT 4 or DOT 5.1 during emergency situations; however, it should be flushed and replaced as soon as possible.

Do not forget that these are just final options. To achieve the best possible performance and defect-free operation of brake systems, use only the fluids recommended by the manufacturer.

The Dangers of Mixing Brake Fluids

We need to explore more than just the reasons why mixing brake fluids is a bad idea.

- Boiling Point Reduction: The boiling point of a mixture of fluids mixed with varying boiling points will be lower than that of its highest rated fluid. This can result in brake fade or failure during high-stress use.

- Chemical Reactions: Additives contained in different brake fluids may not be compatible. Gels or solids formed from these reactions can result in the clogging of brake lines or destruction of seals.

- Seal Degradation: Particular kinds of brake fluids are what brake system seals operate using in their design. A mixture of some fluids can result in the swelling, shrinking or going bad of these seals and subsequently causing leaks therein.

- Corrosion: Varieties of brake fluids in combination may possibly enhance the likelihood of corrosion in a braking mechanism especially when one type has absorbed great amounts of water.

- Unpredictable Performance: The unpredictability of the mixed brake fluid performance features can lead to improper functions of the braking system and unpleasant feeling while driving especially if there is no observable problem at once.

Brake Fluid Maintenance: When and Why to Change

Regular maintenance of brake fluid is one of the most crucial things that guarantee both vehicle performance and safety. But how often should you replace this fluid?

According to most manufacturers, brake fluid should be replaced every two years or after reaching the mileage of thirty thousand. However, this can vary based on:

- Driving conditions

- Climate

- Vehicle type

- Brake system design

Case Study: As stated in a study conducted by the National Highway Traffic Safety Administration in 2018, it was found out that cars with brake fluids which have been in use for more than three years had a chance of experiencing brake problems that was 20% higher.

Indications for brake fluid services:

- Fluid appears dark or dirty

- Brake pedal feels “spongy“

- ABS warning light comes on

- Over two years have passed since any changes were made.

The Importance of Regular Brake Fluid Changes

You have been provided with training data until the deadline of twenty-three Octobers in the year of two thousand and twenty.

- Moisture Contamination: Previously, we elaborated that with time, brake fluid tends to absorb water. This results in a decrease of its boiling point hence causing oxidation in brake system components.

- Wear Particles: Besides, small bits of brakes may actually come off and this will go ahead to contaminate the brake fluid. The plugs thus formed may block different kinds of valves and cause destruction to some parts in a braking system.

- Chemical Breakdown: After a period of time and under high temperatures, additives contained in brake fluid can deteriorate, thereby decreasing its performance.

- Improved Pedal Feel: With fresh brake fluid, the feel of a firm pedal can be revived; thereby increasing your command over the brake system of the vehicle.

- Extended System Life: Commonly, changing fluid for brakes in a car can make their life longer for costly hardware such as ABS pumps and master cylinders.

Factors Affecting Brake Fluid Lifespan

Most manufacturers often suggest to change brake fluid after every 2 years although there are several factors which impact on rate of brake fluid breakdown:

Climate: Moisture possession and fluid decay may quicken in areas that are highly warm and moist.

Driving Habits: Frequent hard braking or driving in mountains may lead to quicker degradation of the fluid due to increased heating.

Vehicle Design: Certain brake mechanisms prevent moisture from soaking in, more than others.

Fluid Quality: More expensive brake fluids could be used for a longer period than cheap varieties.

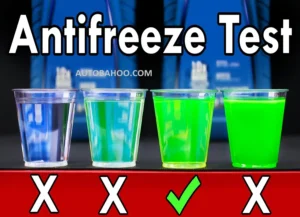

How to Check Your Brake Fluid

Routine assessments might enable you to discover any forthcoming challenges even before they become significant hurdles. Ways of checking brake fluid include:

- Often the brake fluid reservoir is located on a driver’s side by the firewall.

- The degree of fluid should be inspected; it must be located in between the two lines that have been indicated by “Min” and “Max“.

- Inspect the color of the new brake fluid to slightly yellow. Dark fluid indicates contamination.

- Always keep an eye out for any debris or particles that might be present in the fluid.

Remember: Never unscrew brake fluid tank unless you are filling it or replacing the fluid itself. Moisture and impurities can enter when they touch an air molecule.

A Closer Look at Brake Fluid Inspection

Let’s analyze each aspect of the evaluation method:

- Locating the Reservoir: Usually, the brake fluid reservoir is made of a clear plastic that is positioned in proximity to the rear part of the car’s engine compartment as well as the driver’s side. At times, this tank will be labeled with “Brake Fluid” or have a symbol on its cover that indicates it contains brake fluid.

- Checking the Level: It’s required that the reservoir have “Min” and “Max” lines on the side. The fluid level should fall within these lines. In case if it goes below “Min” line, there might be a leak in your brake system or you may have worn out brake pads since they need more fluid to fill space as they wear off.

- Inspecting the Color: The newest brake fluid is colorless and has a faint yellowish hue. The fluid may turn darker in color due to heat and contamination as time goes by. If the liquid resembles dark brown or black then you should certainly consider changing it.

- Looking for Contamination: In addition to color, check for any floating particles or debris in the liquid. This might signify brake system wear or external contaminant ingress.

- Checking the Cap Seal: During your examination of the liquid, take a look at the rubber sealing ring on the lid of the storage tank. If this component gets destroyed, it can permit water vapor and other foreign materials enter into the mechanism.

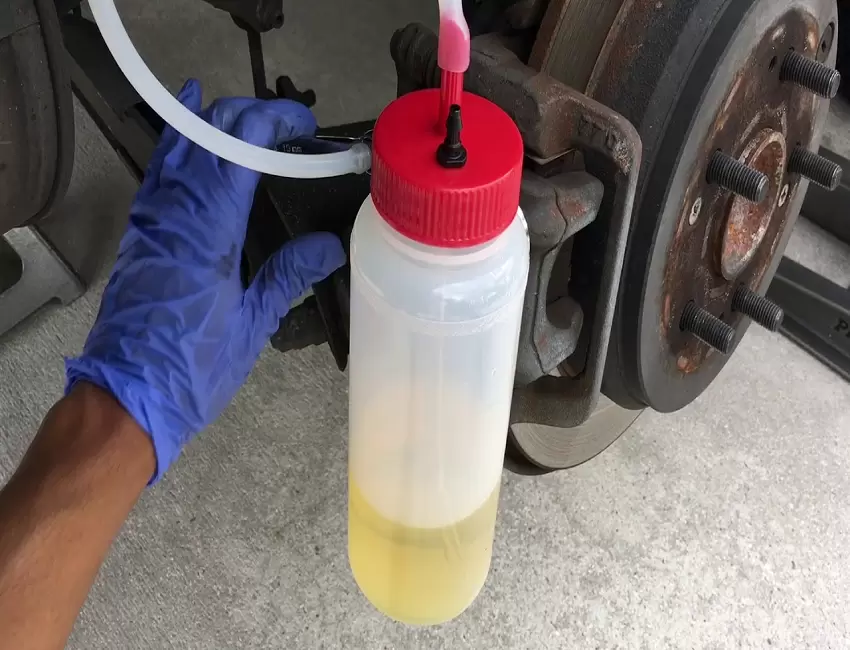

The Complete Flush: Replacing Old Brake Fluid

Bringing brake fluid to its topmost level is easy but replacing it completely entails more complications. To better understand the procedure, this is how it goes:

- Preparation: Gather necessary tools and new brake fluid.

- Draining: Open bleeder valves to drain old fluid.

- Flushing: Pump new fluid through the system.

- Bleeding: Remove any air bubbles from the lines.

- Testing: You must check if your brakes are functioning correctly before driving.

Warning: In case you do not feel okay with this, it is always advisable to let an expert handle it. Otherwise, changing brake fluid improperly may cause your brakes to stop functioning properly.

Directions on How to Bleed Your Brakes

Detailed Steps for a Brake Fluid Flush

Here’s an in-depth discussion of the steps involved in replacing brake fluid for the ones who love to dig deeper into machines:

- Preparation:

- Gather tools: wrench, clear tubing, catch container, new brake fluid.

- Raise and secure the vehicle on jack stands.

- In order to improve access to brake calipers, it’s advisable removing all the wheels.

- Draining:

- Commence with that brake caliper which is located away from the master cylinder (normally rear right).

- Initially, we will need to connect some transparent flexible tubing to the bleeder valve and then position its free end within a receptacle that will receive the fluid as it escapes.

- Open the valve necessary to bleed air out and allow the old fluid to drain.

- Flushing:

- Your assistant should gradually pressure the brake pedal while you monitor the fluid level in the reservoir.

- As required, new liquid must be supplied to the storage tank in order to avoid complete drainage of the container.

- Continue until clear, new fluid comes out of the bleeder valve.

- Bleeding:

- Close the bleeder valve while your assistant holds the brake pedal down.

- Have them release the pedal and repeat the process several times to remove air from the lines.

- Repeat:

- Move to the next closest caliper and repeat the process.

- Continue until all four brakes have been flushed and bled.

Conclusion: Empowering Your Brake Maintenance

Grasping the concept of brake fluid is essential for sustaining the primary safety system of your automobile. Through maintaining observation on the status of your braking liquids and adhering to schedules of good maintenance; you will not only save cash meant for repair works but also guarantee that you can halt in a secured way no matter what takes place.

Remember these key points:

- Use the correct DOT-rated fluid for your vehicle

- Change brake fluid regularly according to your manufacturer’s recommendations

- Never mix different types of brake fluid

- In difficult moments, it is advisable to ask an expert about brake fluid service.

Brakes are what make sure that you do not get injured by colliding with other vehicles on the road while driving your automobiles. Therefore consider giving respect to brakes (and their fluids) that they need; this way they can protect you through long distances.

FAQ:

How often should I change my brake fluid?

Depending on which arrives first, automakers usually recommend replacing brake fluids after 30,000 miles or every two years. But remember to examine your car’s handbook for detailed suggestions on this matter.

Can I mix different types of brake fluid?

It’s not suggested to combine varying kinds of brake fluids. Mixing them can damage your brake system’s performance and safety. Always follow the recommendation given by your car maker regarding its type.

What happens if my brake fluid gets low?

Can leakages or worn out brake pads be indicated with less brake fluid? It may result into low braking efficiency or even brake failure. Check levels regularly and top up if needed.

With over 5 years of dedicated experience in the automotive industry, I am passionate about all things automotive. My journey began with a deep curiosity for automobiles, which led me to delve deeper into their mechanics, technology and trends. My expertise spans various aspects of the automotive world, from the latest electric vehicles to classic car restoration techniques. Through my articles, I aim to share my knowledge and insights, helping readers stay informed and inspired in the fast-paced world of the automobile.