In terms of automotive safety no systems are as important as your car Problem with Your Brakes system. They are the silent workers of every journey who only get noticed during emergency moments.

What do you do when the brakes start failing? Are there any early warning signs that help avoid major malfunctions that could lead to accidents?

This article will guide you through the seven most prominent indicators that your brake may need some attention this way you will be able to detect trouble well in advance thus averting danger for touring with relatives.

Moreover we will take a closer look at how car braking systems function discuss their common problems and give practical tips for ensuring your vehicle remains roadworthy.

Understanding Your Car’s Brake System: A Quick Overview

Prior to discussing the red flags let’s take the time to understand how the brake system in your car works. This understanding will aid you in deciphering the signals that your vehicle may be throwing at you.

Components of a Modern Brake System

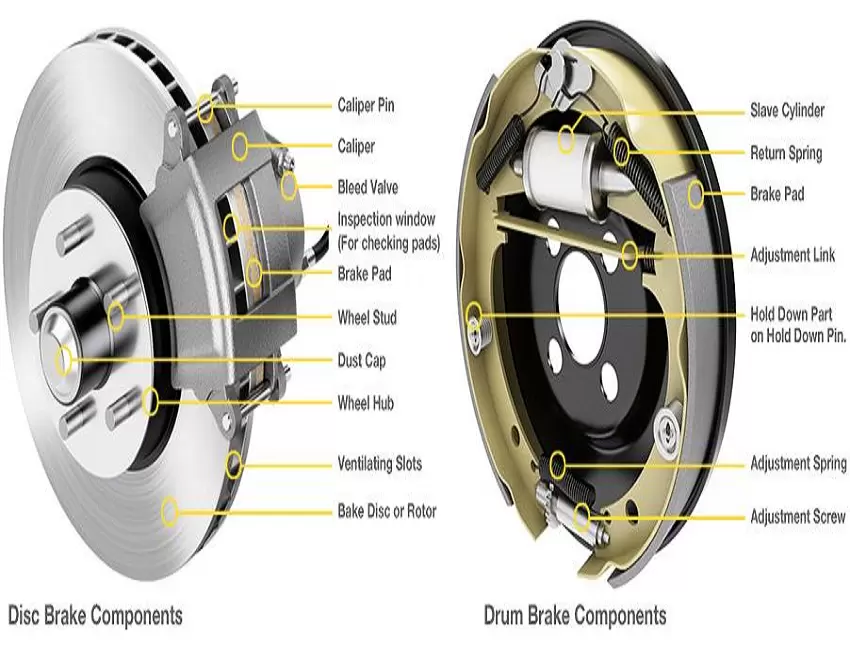

A vehicle’s stopping mechanism is not simplistic but a combination of several pieces acting together. Here are important elements found therein:

- Brake pedal: The interface that is connecting your foot with the braking system.

- Brake booster: It increases the force that you apply on the pedal.

- Master cylinder: It takes mechanical force and turns it into hydraulic pressure.

- Brake lines: To the wheels, hydraulic brake fluid must be transported.

- Brake calipers (for disc brakes):Brake pads must be held together tightly by the rotor.

- Brake pads: The material used for friction which applies force on the rotor.

- Rotors (for disc brakes): The discs that spin which the pads cling to

- Drum brakes (on some vehicles): An older style of brake using shoes inside a drum

How These Parts Work Together

Once a brake pedal is pressed then it affects other reactions that follow;

- Your foot’s force is amplified by the brake booster

- This force is converted into hydraulic pressure by the master cylinder

- The brake fluid conveys this pressure throughout the brake lines

- In disc brakes calipers press the pads against the rotors

- In drum brakes, wheel cylinders push brake shoes against the drum

- The resulting friction slows and stops your vehicle

With the fundamentals out of our way, let us now delve into seven warning signs that may point towards some brake problems.

7 Red Flags: Recognizing Brake Issues Before They Become Dangerous

1. Your Dashboard’s Warning: The Brake Light Illuminates

An obvious indicator of brake malfunction and issues involves having the brake warning light turn on. Though this may appear to be insignificant it holds significant weight within your vehicle’s dashboard.

What it means and potential causes:

- Low brake fluid level

- Engaged parking brake

- Sensor malfunction

- ABS system issue (if it’s the ABS light)

When to act immediately: Pull over immediately if the light comes on while driving, especially if the brakes begin to react abnormally. Don’t keep driving until you get a mechanic to look at it.

If you don’t want to look into it you have it the way it goes and Mike Calkins (AAA’s director of technological support) said: “The brake warning light is your car’s way of saying, ‘Hey, pay attention to me!’” To ignore this is tantamount to refusing to respond when your vehicle calls for aid.

In today’s automobiles there can be distinct indicators for parking brake, anti-lock brake system as well as general braking problems independently. Find out about unique warning lights that are particular to different cars by referring to the user manual of the vehicle.

Case Study: The Importance of Heeding Warning Lights

Cited by the National Highway Traffic Safety Administration (NHTSA) in a report released in 2018, 2% of total vehicle accidents that happened in America were because of brake related problems. Many of these drivers did not realize that their car’s brake warning light was on or chose to ignore it completely.

2. The Screech of Trouble: High-Pitched Squealing Noises

It’s a consciously designed alert mechanism incorporated in your auto by the maker that produces that sound in high frequency when you step on the brakes and it’s not only annoying.

Distinguishing between normal and abnormal sounds:

- Normal: A light squeak after your car has been sitting in humid conditions or after a rainstorm

- Abnormal: Each time the brakes are applied there is an unending, piercing whistle that is quite shrill.

The role of brake pad wear indicators: A lot of brake pads have attached small pieces of metal known as wear indicators. These pieces will touch the rotor if the material has worn down to a particular extent producing an audible sound; this is how you will know when your car needs new brake pads.

The genius of this design is its simplicity. The pad wear indicator is typically a small hardened steel clip inserted into the brake pad material. As the pad wears down through normal use this clip gets closer and closer to the rotor surface. A distinctive squeal is created as a result of the clip coming into contact with the rotor at the time of braking when the pad material has worn out up to a point where it requires being replaced (usually when there is approximately 25% of remaining pad material).

The science behind the squeal: That obnoxious sound is nothing more than vibrations that occur because of frictions between the metal wear indicators and the moving rotor. These vibrations happen at such frequencies that make it scream-like. For this purpose it has an annoying design!

3. Grinding Gears: The Ominous Sound of Metal-on-Metal

If squealing graduates to a harsh grinding noise you’ve moved beyond a warning into active damage territory.

Why this noise occurs and what it indicates: Grinding typically means your brake pads have worn completely through. The backing plate of the pad (or in worse cases, the caliper itself) is now making direct contact with the rotor.

The potential damage to rotors and calipers: This metal on metal contact can quickly score or warp your rotors leading to an expensive repair. In severe cases, it can damage the calipers potentially compromising your entire braking system.

Let’s break down the potential costs:

| Component | Average Replacement Cost |

| Brake Pads | $100 – $300 per axle |

| Rotors | $200 – $400 per axle |

| Calipers | $300 – $800 per caliper |

The simple act of replacing a pad may appear harmless at first glance; however if left unattended it can rapidly turn into an extremely costly restoration.

The dangers of driving with grinding brakes: Driving with squeaking brakes entails more than just cost. It is associated with many dangers such as increasing the stopping distance and possible brake failure. Most particularly in wet conditions, scored rotors cannot disperse water clearly resulting in hydroplaning during braking.

4. Shaky Ground: Vibrations in the Steering Wheel or Brake Pedal

When you hit the brakes and feel a shake in your car it’s like the vehicle is communicating something that is wrong.

Possible causes: warped rotors, uneven brake pad wear

- Warped rotors: Heat and stress can cause rotors to become slightly misshapen

- Uneven pad wear: Can result from sticking calipers or improper previous installation

How vibrations affect stopping distance and control: Vibrations do not only feel annoyingly, but they could also lead to a longer distance before your car stops and loss of control over the automobile particularly when you are about to apply emergency brakes.

The science of brake vibrations: When a warped rotor is installed it does not have a smooth surface for braking pads to interact with. The pads slide in and out quickly as the high and low parts of the disk rotor pass beneath them. All these factors affect the brake pedal through the hydraulic system and also affect the steering via suspension.

When this happens it might lead to your ABS system engaging even when you are not stepping on brakes because vibrations are misinterpreted by the system as a wheel lockup situation. This can further increase your stopping distance.

Diagnosing vibrations:

- Mainly if the steering wheel vibrates, there may be a problem with the front disc brakes.

- If you feel more in your seat or even the car as a whole it may signify there is something wrong with rear brakes (disc or drum).

- When you don’t brake but still get vibrations it might be due to either incorrect balancing of the tires or suspension and not an issue with brakes at all.

5. The Nose Knows: Burning Odors While Braking

Your nose can be a powerful diagnostic tool when it comes to brake problems.

Identifying brake-related smells:

- Burning rubber: Could indicate a stuck brake or a slipping drive belt

- Acrid chemical smell: Might be overheated brake fluid or pads

Overheating issues and their implications: Overheating brakes can lead to brake fade and a temporary loss of stopping power. In extreme instances this can cause your brake fluid to start boiling which will result in total loss of brakes control.

The chemistry of brake overheating: Most brake fluids are made of glycols which have a tendency of sucking into them water content with time. This lowers its boiling point. When brakes overheat this moisture laden fluid can boil creating gas bubbles in the brake lines. Unlike liquid these gas bubbles are compressible which means pressing the brake pedal may simply compress the bubbles rather than applying pressure to the brakes.

Preventing and addressing overheating:

- Avoid “riding” the brakes especially on long downhill stretches. Use engine braking by downshifting instead.

- A burning odor could arise while on a drive; forget not your brakes need some time out to cool off if this happens simply park at the side of the road.

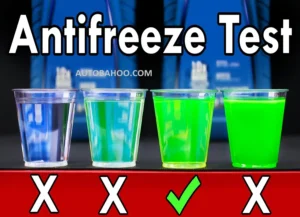

- Your vehicle’s maintenance schedule suggests that it is important to inspect and replace brake fluid. Most manufacturers suggest that this be done at intervals of two years.

When it comes to stocking up on brake fluids high quality brands such as Prestone Brake Fluid serve this purpose well because they have been designed to resist high temperatures and absorb lesser amounts of water in your vehicle thus preventing an over-heat occurrence from happening.

6. Sinking Feeling: A Soft or Spongy Brake Pedal

The brake pedal might feel like something resembling a marshmallow instead of being a solid object that brings a halt implying that there is indeed something wrong with it.

Breaking fluid escapes from its containers while at the same time air bubbles enter through them:

Air in the brake lines vs. brake fluid leaks:

- Air in the lines: Can occur after brake service if the system wasn’t properly bled

- Brake fluid leak: A more serious issue that requires immediate attention

The dangers of reduced brake responsiveness: A soft pedal means you have to press farther to get the same stopping power. In an emergency. These spare millimeters might have made all the difference between halting on time or not.

The hydraulics of the brake pedal feel: The functioning of your automobile’s braking mechanism is based on hydraulics. It is worth noting that this explanation is designed for the purpose of simplifying the process that happens when brakes are applied. If you want a detailed technical discussion on each component involved and how they work together, it would take a lot of time and effort to put everything in one place.

The hydraulic fluid is in a brake line which forms an enclosure that makes pressure when the pedal is pressed down. This pressure is then delivered to the calipers or cylinders to push on the pads or shoes.

When there is air captured inside the parameters, any tapping will create an elastic like feel which tends to make braking ineffective because it will have less friction. Likewise pressing down the pedal may not produce enough pressure for effective braking if there is a leak somewhere else in the system.

Diagnosing a spongy brake pedal:

- Examine the liquid fraction of braking fluid in the engine’s master-cylinder compartment. In case it runs low, there could be seepage somewhere in the system.

- Observe for moist places or damp patches on the tires and beneath the vehicle.

- Depress the brake pedal without starting the engine if it moves down to ground level, then it’s evident that there is an issue with the master cylinder.

- On one hand, if pressing down on the pedal appears fine at first but when held back results in sinking all way low either brake lines or calipers might be leaking.

7. Veering Off Course: Car Pulls to One Side When Braking

It’s time to have a check-up if your car appears to be in control of itself when you press the brakes.

Uneven brake pad wear, stuck calipers, or alignment issues:

- Uneven wear: One side grips more strongly than the other

- Stuck caliper: Causes one wheel to brake more than others

- Alignment problems: Can cause uneven tire wear affecting braking

How this affects vehicle control and tire wear:

Furthermore, aside from the apparent dangers of erratic braking the problem could result in the premature and uneven wear of your tires which may ultimately be more costly in the long run.

The physics of uneven braking: When you consider applying brakes, the car weight shifts forward which increases the downward force on front wheels. Therefore the majority of cars have larger front disc brakes compared to those at the rear. On the other hand, if one side braking is more effective than another it means that there is an unbalanced force and the vehicle will tend to go in either direction.

Diagnosing pulling under braking:

- Check tire pressure: Pulling may occur when a vehicle is not braking at all due to its tires being inflated in an unequal manner.

- Inspect brake pads: Uneven wear between the left side and right side needs to be checked.

- Check for stuck calipers: If the caliper won’t totally release constant drag will hence occur on one wheel.

- Examine brake hoses: A collapsed hose can prevent proper brake release.

- Consider alignment: While not directly a brake issue, poor alignment can cause uneven tire wear that affects braking.

Taking Action: What to Do When You Spot These Signs

Only understanding the symptoms is just part of the fight. Equally important is knowing how to react.

The importance of prompt brake inspections

Never procrastinate regarding little problems; they might escalate into serious problems one day. The regular inspections can help detect wear and tear before it turns into something dangerous.

DIY checks vs. professional diagnostics

While some checks (like visually inspecting pad thickness) can be done at home a professional has the tools and expertise to fully evaluate your braking system.

DIY Brake Check Checklist:

- Visual inspection of brake pads (through wheel spokes)

- Check brake fluid level and condition

- Look for leaks around wheels and under the car

- Test brake pedal feel

- Listen for unusual noises during braking

When to call in the pros:

- If you hear grinding or persistent squealing

- Should the brake pedal feel soft as well as spongy?

- Should the car pull towards one side while braking?

- Should the brake warning sign be on?

- One complete inspection should be every year.

Preventive Measures: Keeping Your Brakes in Top Shape

It is better to maintain brakes with a small preventive measure than to employ many corrective measures.

Regular maintenance schedules

Follow your vehicle manufacturer’s recommended service intervals Typically it should be checked at least yearly but may not exceed 12,000 miles.

Driving habits that extend brake life

- Avoid “riding” the brakes

- Anticipate stops to break gradually

- Remove excess weight from your vehicle

- In manual transmission vehicles use engine braking when appropriate

The science of brake wear: Brake pad wear is influenced by several factors:

- Speed: Wear increases exponentially with speed

- Temperature: Higher temperatures accelerate wear

- Pressure: Higher pressure (harder braking) increases wear

- Material: Different pad compounds wear at different rates

By adopting smooth anticipatory driving habits you can significantly reduce the wear on your brakes.

The Cost of Ignoring Brake Problems

When it pertains to problems with brakes procrastination can be expensive.

Safety risks

The most important consideration is safety. Faulty brakes increase your risk of accidents potentially putting lives in danger.

Financial implications of delayed repairs

What might start as a simple pad replacement can escalate to rotor resurfacing or replacement caliper repairs or even master cylinder issues if left unchecked.

Comparative Costs of Brake Repairs:

| Repair Type | Average Cost Range |

| Brake Pad Replacement | $150 – $300 per axle |

| Rotor Resurfacing | $50 – $100 per rotor |

| Rotor Replacement | $200 – $400 per rotor |

| Caliper Replacement | $300 – $800 per caliper |

| Master Cylinder Replacement | $400 – $600 |

The snowball effect of neglected brakes: Neglecting braking problems not only exposes you to danger but also triggers chain of events:

- Worn pads can damage rotors

- Damaged rotors can cause uneven wear on new pads

- Uneven wear can lead to pulling which affects alignment

- Poor alignment causes uneven tire wear

- Uneven tires can cause suspension issues

What starts as a simple pad replacement can quickly turn into a much more extensive (and expensive) repair job.

Conclusion: Prioritizing Brake Health for Peace of Mind

Brakes are the most critical part of your safety system in an automobile. When you are educated about seven indicators that are cautioning you, and you take action on time, then not only will you keep your ride but also transport them safely along other public roads with yourself.

It’s better to be safe than to be sorry when it comes down to breaks. So if there is any uncertainty on the functioning of your car’s brake system, don’t fear consulting an expert. Thus, in future, this will help in preventing expensive repairs and saving cash.

Thus when it comes down to learning how brakes work; this helps one recognize little problems before they escalate. From the telly

FAQ: Problem with Your Brakes

How often should I have my brakes inspected?

To ensure that you do not experience catastrophic failures brought about by brake failure, it is best to inspect brakes annual or once every 12000 miles. Any abnormal sounds and vibrations or dead weight must indicate their check (Wheeler, 2017).

What’s the difference between disc brakes and drum brakes?

On the one hand, disc brakes are designed to allow the brake pads to be applied onto rotors by using pins, while on the other hand drum brakes employ brake shoes that press against the inner surface of a drum. Modern day vehicles use disc brake systems because they provide better performance and cooling.

How long do brake pads typically last?

Brake pad’s life span is not the same for all cars but also varies with rate of use or frequency of replacement, type of pads used and various factors related to road conditions. Usually, they can last between thirty thousand and seventy thousand miles on average. City driving with frequent stops wears pads faster than highway driving.

With over 5 years of dedicated experience in the automotive industry, I am passionate about all things automotive. My journey began with a deep curiosity for automobiles, which led me to delve deeper into their mechanics, technology and trends. My expertise spans various aspects of the automotive world, from the latest electric vehicles to classic car restoration techniques. Through my articles, I aim to share my knowledge and insights, helping readers stay informed and inspired in the fast-paced world of the automobile.