Choosing the Ideal Coolant for Your Heavy-Duty Vehicle

When it comes to maintaining the health and performance of your heavy goods vehicle ( HGVs), one of the most critical considerations is the coolant or antifreeze you use.

The right coolant can mean the difference between a well-protected, efficiently running engine and one that is susceptible to costly damage and breakdowns.

In this comprehensive guide, we’ll explore the importance of proper coolant selection for HGVs, the key differences between light-duty and heavy-duty formulations, and introduce a premium solution that exceeds industry standards.

Understanding HGVs Cooling Systems

Heavy-duty diesel engines face unique challenges that set them apart from regular vehicles. Think of your HGVs engine as a powerhouse that’s constantly working under extreme pressure. These engines generate massive amounts of heat and need specialized cooling solutions to handle it.

Cavitation Corrosion Protection: The Silent Engine Killer

Here’s something fascinating: When your engine runs, the pistons create tiny vacuum bubbles in the coolant next to the wet sleeve liners. When these bubbles collapse, they can literally eat away at the metal – that’s pitting cavitation. A good HGVs antifreeze contains special additives to prevent this damage.

Protection Mechanisms Table:

| Additive Type | Protection Offered | Common In |

| Nitrites | Cavitation protection | Traditional heavy-duty coolants |

| Molybdates | Liner protection | Modern formulations |

| Silicates | Aluminum protection | Some hybrid coolants |

| Organic acids | General corrosion protection | OAT coolants |

The Real Cost of Using Wrong Coolants

I’ve seen plenty of preventable engine failures caused by using the wrong coolant. Here’s a real case study:

“We had a fleet operator who switched to light-duty antifreeze to save money. Within 18 months, three of their trucks needed liner replacements due to cavitation damage. The repair costs were ten times what they’d saved on coolant.” – John Smith, Fleet Maintenance Director

Damage Comparison Table:

| Issue | Repair Cost | Downtime | Prevention |

| Liner pitting | $3,000-5,000 | 3-5 days | Proper HGV coolant |

| Cooling system corrosion | $2,000-4,000 | 2-4 days | Regular testing |

| Heat exchanger failure | $1,500-3,000 | 2-3 days | Correct maintenance |

The Importance of Proper Coolant in HGVs

The engine cooling system in an HGVs plays a vital role in maintaining optimal performance and longevity. As these vehicles are subjected to heavy loads, high temperatures, and demanding operating conditions, the coolant must be able to effectively:

- Absorb and dissipate heat generated by the engine

- Prevent corrosion of critical engine components

- Inhibit scale and deposit buildup

- Protect against cavitation and pitting of wet sleeve liners

Using the wrong coolant or allowing it to degrade over time can lead to a host of problems, including reduced heat transfer, accelerated wear on engine parts, and even catastrophic failure. This not only impacts the vehicle’s performance and fuel efficiency but can also void the manufacturer’s warranty if damage occurs.

Understanding Heavy-Duty Coolant Requirements

While light-duty vehicles typically use a one-size-fits-all antifreeze, the cooling system demands of HGVs require a more specialized formula. Heavy-duty coolants are engineered to withstand the higher temperatures, pressures, and chemical exposures found in commercial and industrial applications.

Some key differences between light-duty and heavy-duty coolants include:

| Characteristic | Light-Duty Antifreeze | Heavy-Duty Coolant |

| Additive Package | Silicate-based | Organic Acid Technology (OAT) or Hybrid OAT |

| Nitrite Content | Typically lower | Typically higher |

| Molybdate Content | Typically lower | Typically higher |

| Service Life | 2-5 years | 3-6 years |

| Compatibility | Passenger vehicles | Commercial trucks, buses, and equipment |

Heavy-duty coolants are formulated to provide enhanced protection against:

- Cavitation corrosion, a phenomenon that can pit and erode wet sleeve liners

- Scaling and deposit buildup that can impede heat transfer

- Aluminum corrosion, a common issue in modern engine designs

Additionally, the longer service life of heavy-duty coolants helps minimize maintenance costs and downtime for HGV fleets.

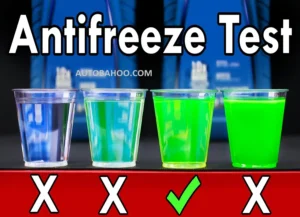

Selecting the Right Coolant for Your HGV

When choosing a coolant for your heavy-duty vehicle, it’s essential to identify the specific requirements outlined by the manufacturer. This information is typically found in the owner’s manual or can be obtained directly from the vehicle or engine maker.

Key factors to consider when selecting a heavy-duty coolant include:

- Coolant type (conventional, OAT, HOAT, etc.)

- Antifreeze concentration (typically 50/50 or 60/40 coolant-to-water ratio)

- Compatibility with the materials used in your engine’s cooling system

- Compliance with industry specifications such as ASTM D6210, TMC RP 329, or OEM standards

Using the wrong coolant can lead to serious issues, including:

- Accelerated corrosion of aluminum, copper, solder, and other metal components

- Degradation of elastomeric seals and hoses

- Reduced heat transfer and engine overheating

- Potential voiding of the manufacturer’s warranty

To ensure maximum protection and performance, it’s crucial to follow the coolant recommendations provided by your HGVs manufacturer.

Introducing Prestone Command Heavy-Duty Coolant

Prestone, a leading name in automotive fluids, has developed a premium heavy-duty coolant solution specifically engineered for the demands of commercial and industrial vehicles.

Prestone Command Heavy-Duty Coolant is formulated to exceed industry standards, providing exceptional protection and long-lasting performance.

Key Features and Benefits:

Organic Acid Technology (OAT) Formulation:

Prestone Command utilizes an advanced OAT additive package that outperforms traditional silicate-based coolants. This technology provides superior protection against corrosion, scaling, and cavitation.

Enhanced Cavitation and Corrosion Protection:

The coolant’s specialized additive package, including higher levels of nitrites and molybdates, helps safeguard critical engine components like wet sleeve liners against pitting and erosion.

Compatibility with Modern Engine Materials:

Prestone Command is engineered to be compatible with the aluminum, brass, copper, solder, and elastomeric materials found in today’s heavy-duty engines, ensuring long-term protection.

Extended Service Life:

With a recommended service interval of up to 6 years or 600,000 miles, Prestone Command helps minimize maintenance costs and downtime for HGV fleets.

Inhibition of Scale and Deposit Formation:

The coolant’s advanced chemistry effectively prevents the buildup of scale and deposits that can impede heat transfer and engine cooling.

All-Season Performance:

Prestone Command provides year-round protection, with a wide operating temperature range and effective freeze and boil-over protection.

Ease of Use:

This heavy-duty coolant is pre-diluted and ready to use, eliminating the need for on-site mixing and reducing the risk of improper dilution.

By choosing Prestone Command Heavy-Duty Coolant, HGVs owners and fleet managers can have confidence that their engines are safeguarded against the demanding conditions they face, helping to maximize uptime, efficiency, and longevity.

Heavy-Duty vs. Light-Duty Antifreeze: Key Differences

While light-duty and heavy-duty coolants may appear similar, there are crucial distinctions in their formulations and intended applications. Understanding these differences is essential to ensuring the proper protection for your HGVs engine.

The primary differences lie in the additive packages used in each type of coolant:

Light-Duty Antifreeze:

Typically silicate-based, light-duty antifreeze is designed for use in passenger vehicles with smaller, less demanding cooling systems.

These additives can provide adequate protection in milder operating conditions but may not hold up well to the higher temperatures and pressures found in commercial vehicles.

Heavy-Duty Coolant:

Formulated with Organic Acid Technology (OAT) or Hybrid OAT (HOAT) additives, heavy-duty coolants are engineered to withstand the rigors of commercial and industrial applications.

These specialized additives offer enhanced protection against corrosion, cavitation, and deposit formation, making them better suited for the demands of HGVs engines.

Additionally, heavy-duty coolants typically contain higher concentrations of molybdates and nitrites, which are critical for safeguarding wet sleeve liners against pitting and erosion. This cavitation corrosion protection is crucial for ensuring the long-term reliability of heavy-duty engines.

The service life of light-duty and heavy-duty coolants also differs significantly. While light-duty antifreezes may need to be replaced every 2-5 years, heavy-duty coolants can often last 3-6 years or more, reducing maintenance costs and downtime for HGVs fleets.

Ultimately, the decision to use a light-duty or heavy-duty coolant should be based on the specific requirements of your HGVs engine and cooling system. Consulting the manufacturer’s recommendations and using the appropriate coolant for your vehicle is essential for maintaining optimal performance and protecting your investment.

FAQ: Coolant or Antifreeze in HGVs

Q: Does it matter what coolant you use in a diesel truck?

A: Yes, the type of coolant used in a diesel truck matters. Diesel engines have different cooling system requirements than gasoline engines, so using the wrong coolant can lead to corrosion, deposits, and reduced engine life. Choosing a heavy-duty, diesel-specific coolant formulation is crucial for ensuring optimal performance and protection in a diesel truck.

Q: Can you use regular antifreeze in a semi truck?

A: No, regular antifreeze is not suitable for use in a semi-truck. Semi-trucks require a heavy-duty, commercial-grade coolant formulated to withstand the higher temperatures, pressures, and demands of a commercial diesel engine. Using the wrong coolant can cause damage to the engine and cooling system components, leading to costly repairs.

Q: Does it matter which antifreeze coolant I use?

A: Yes, it absolutely matters which antifreeze coolant you use. The type of coolant greatly impacts engine protection, compatibility, and longevity. Using the wrong coolant can lead to corrosion, deposits, and even engine failure. It’s critical to select a coolant specifically formulated for your vehicle’s make, model, and engine type.

Q: What happens if you put the wrong antifreeze in your truck?

A: Using the wrong antifreeze in your truck can have serious consequences. It may lead to accelerated corrosion, scale buildup, and even engine damage. Incompatible coolants can compromise heat transfer, causing overheating issues. Mismatched additives can also degrade seals and gaskets. To avoid these problems, always use the coolant recommended by your truck’s manufacturer.

Q: What is the best coolant for a heavy duty truck?

A: The best coolant for a heavy-duty truck is one specifically formulated for commercial and industrial applications. Look for a heavy-duty coolant that uses Organic Acid Technology (OAT) or Hybrid OAT (HOAT) additives, provides enhanced corrosion and cavitation protection, and has a long service life to minimize maintenance costs.

Conclusion

In the world of heavy-duty vehicles, where performance, efficiency, and reliability are paramount, the choice of coolant or antifreeze can make all the difference.

By understanding the unique requirements of HGVs engines and selecting a premium heavy-duty coolant like Prestone Command, you can help ensure your vehicle’s cooling system is up to the task, maximizing engine protection and minimizing costly downtime.

Remember, when it comes to HGVs maintenance, using the right coolant is not just a matter of preference – it’s a necessity. Invest in a solution that exceeds industry standards and gives you the peace of mind that your heavy-duty engine is running at its best, no matter the conditions it faces.

With over 5 years of dedicated experience in the automotive industry, I am passionate about all things automotive. My journey began with a deep curiosity for automobiles, which led me to delve deeper into their mechanics, technology and trends. My expertise spans various aspects of the automotive world, from the latest electric vehicles to classic car restoration techniques. Through my articles, I aim to share my knowledge and insights, helping readers stay informed and inspired in the fast-paced world of the automobile.