Have you been thinking of upgrading your cars appearance with a Vinyl To Wrap A Car but aren’t sure how much material is really required? Proper measurement and estimating are crucial first steps to achieving a professional looking finished product.

In this in depth guide we’ll explain all the key factors to consider and steps to take for accurately calculating your vehicle’s true vinyl needs.

Measure Twice, Order Once:

The most precise way to determine how much vinyl wrap stock will be needed is to physically measure the vehicle yourself using a tape measure.

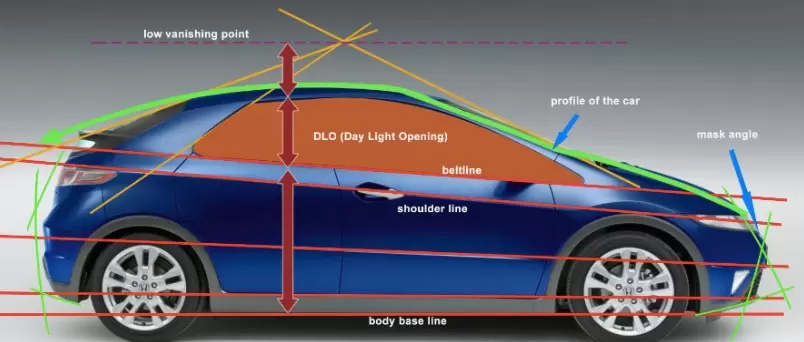

Start by tracing the full outer profile of the entire car, including each individual panel. Pay close attention to any complex curves, crevices or other irregular shapes that may require extra wrap material to fully conform.

You’ll also want to measure each section like doors, quarter panels and the hood separately. This allows for precise ordering of the exact dimensions required for odd shaped trim pieces.

Don’t forget to account for recessed areas around wheel wells that often demand multiple layers of overlapping vinyl cuts. Areas like door jambs may also need digital wraps depending on desired cosmetic outcomes.

For trucks and SUVs with roof coverage goals, make sure to also trace out roof dimensions if you’ll be unwrapping this section.

Many experienced wrappers find it easier to apply and hide seams on the roof when it’s detached beforehand. Be sure to document all measurements in written or digital form for easy use later in the vinyl ordering and supply planning process.

Measure What Matters For Your Project Scope:

Of course, overall vehicle size plays a big role in estimated vinyl quantities. Compact cars generally require far less material than a family-sized van or pickup.

But don’t forget to factor in your specific project scope and goals too. A simple two-tone body panel wrap may consume less vinyl than a multi-color abstract graphic design spanning the whole vehicle.

Tackling extras like bed liners, grilles or bumpers also adds to quantities. Partial equipment wraps may only need short rolls in contrast to full coverage schemes.

Detail oriented wraps extending vinyl to wrap a car coverage onto emblems, mirrors or other trim pieces demands additional material quantities as well.

It’s also important to match your measurements to desired qualities in purchased materials. Thicker casting or overlaminate vinyls are more durable but come at higher square footage costs than basic single-ply wraps. Balancing needs against budget is part of vinyl planning.

Convert Dimensions Into Square Footages:

Once all measurements for your vehicle have been noted in linear inches or feet, the next step is to convert them into calculated square footage amounts.

Simply take the total combined length and divide it by the standard conversion factor of 144 to determine square inches or feet required.

Be sure to account for partial dimensions or strangely shaped areas that may require estimating fractional square foot quantities. Break out body sections, trim add-ons and individual panels into easy to reference quantity categories as well.

Factor In Wrapping Contingencies

Even for experienced wrappers, initial measurements almost never perfectly translate into the actual amount of vinyl required for a flawless result.

To prevent running short, it’s prudent to factor in material waste contingencies from the start. Expect to use 5-15% more vinyl wrap stock than your calculated square footage to cover contingencies like:

- Primer/application solution overlays on cut edges

- Practice applications and template measurements

- Cutouts and obstacles like door handles

- Difficult or hard to access body contours

- Unavoidable mistakes common even to pros

Quality vinyl retailers understand this reality and will generally have overage policies if you fall short for unexpected wrap challenges. But it’s still better to simply overestimate quantities planned from the beginning.

Compare Sizes To Available Materials:

Major vinyl suppliers offer a wide range of roll sizes from small sample lengths to bulk commercial rolls. Most common home shop sizes range between 5-50 square feet.

Carefully compare your estimated total needs against standard increment measurements to determine how many rolls are required and of which sizes when placing supply orders.

Mixing roll sizes may be necessary to achieve an exact quantity. Factor in any minimum or rush shipping fees as well to ensure availability timing aligns with your planned install schedule.

Finished materials like cast or certain specialty Vinyl To Wrap A Car films may carry premium costs versus basic economy wraps too dependent on project goals.

Re-Measure For Long Term Projects: Vinyl To Wrap A Car

For large commercial jobs spanning many weeks or months, it’s a smart idea to periodically re-check measurements throughout the process.

Vehicles settle and sheet to expand after some break in driving time. Re measuring allows for ordering any small supplemental material needs with room for mistakes to develop later on.

Some higher end services also offer replacement vinyl warranties for years to cover typical expansion and contraction cycles or minor accidents down the road as a perk. But being properly stocked originally saves headaches of running out part way through wrap projects.

Create Backup Plans For Overages:

If some extra vinyl does remain after completing a project, creatively repurpose it for smaller secondary applications rather than wasting usable material. Leftovers can be held onto for touch ups, door jambs or unexpected needs on future jobs.

Skilled wrappers may also give or donate small amounts to local youth car clubs for learning experience projects.

Many organizations welcome donated vinyl for members to practice techniques and develop new skills. Responsible disposal of scraps like through licensed films recyclers is another eco-friendly option.

By taking meticulous measurements, factoring in generous contingencies and thoughtfully planning quantities against standard roll sizes, any driver can feel completely confident they’ve acquired exactly the right amount of vinyl needed for fully wrapping their vehicle.

Proper preparation at the measurement stage helps guarantee even novice wrappers achieve a seamless professional finish from start to complete coverage of their ride.

FAQ:

Q:How many sq ft to wrap a car?

A:250 square feet.

Q:How many metres of vinyl to wrap a car?

A:Small size cars can be fully wrapped with 50 to 55 feet / 15 to 16.8 meters.

Q:How long does a car wrap last?

A:three to five years.

Q:How thick is car vinyl wrap?

A:3-4 mil.

Q:How much wrap is needed for SUV?

A:50 feet to 75 feet.

Conclusion:

Properly estimating Vinyl To Wrap A Car needs requires time spent measuring accurately and carefully planning for all project details and contingencies.

But getting this vital pre installation process right results in a transformation that looks completely factory original. With the right quantities of high quality material perfectly matched to any vehicle’s specific dimensions and planned design, the full potential of the vinyl wrapping process can be seamlessly realized. Follow these steps to calculate true vinyl requirements and any driver can confidently embark on the exciting journey of creatively customizing their ride’s appearance through the versatile medium of automotive-grade wrap films.

With over 5 years of dedicated experience in the automotive industry, I am passionate about all things automotive. My journey began with a deep curiosity for automobiles, which led me to delve deeper into their mechanics, technology and trends. My expertise spans various aspects of the automotive world, from the latest electric vehicles to classic car restoration techniques. Through my articles, I aim to share my knowledge and insights, helping readers stay informed and inspired in the fast-paced world of the automobile.